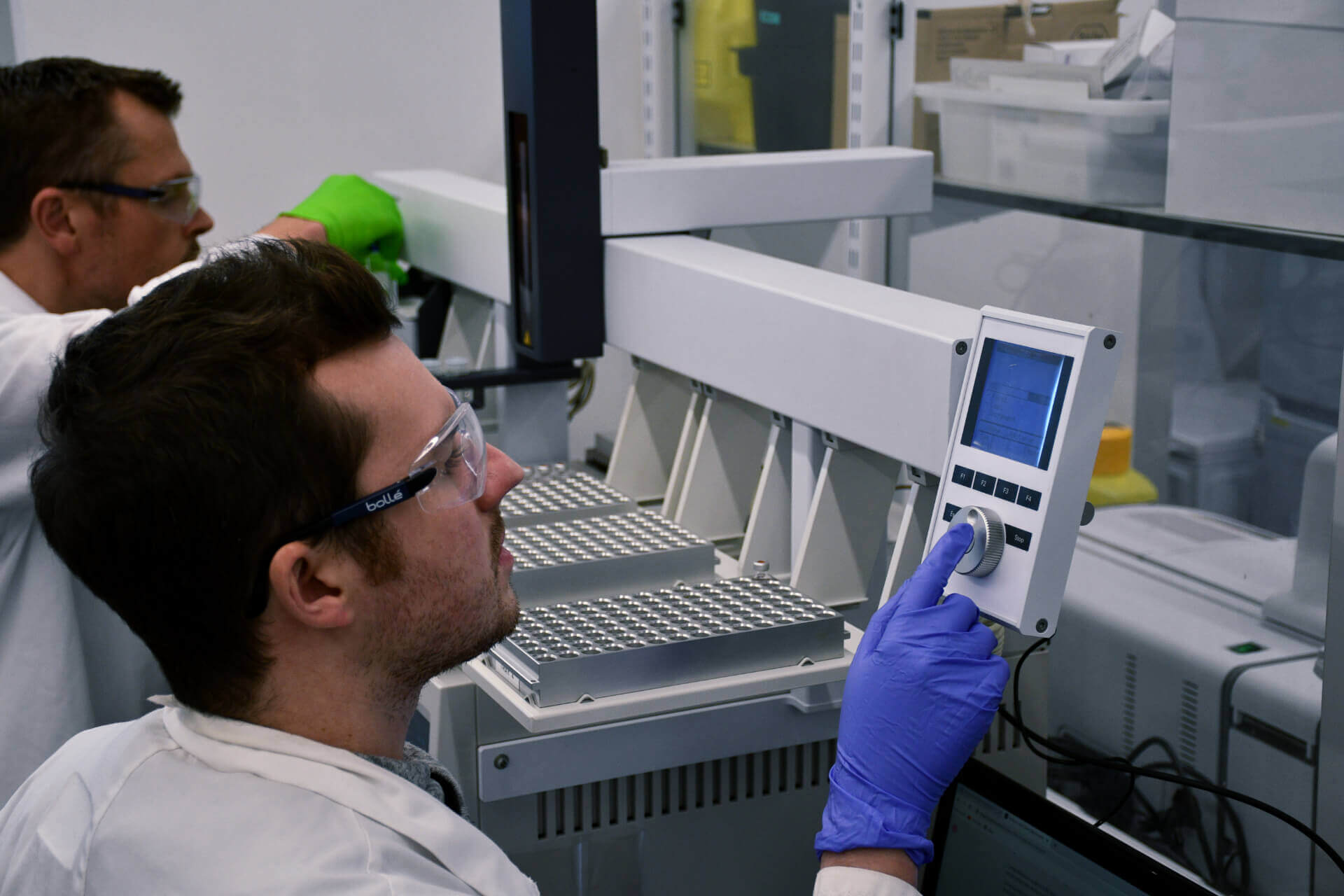

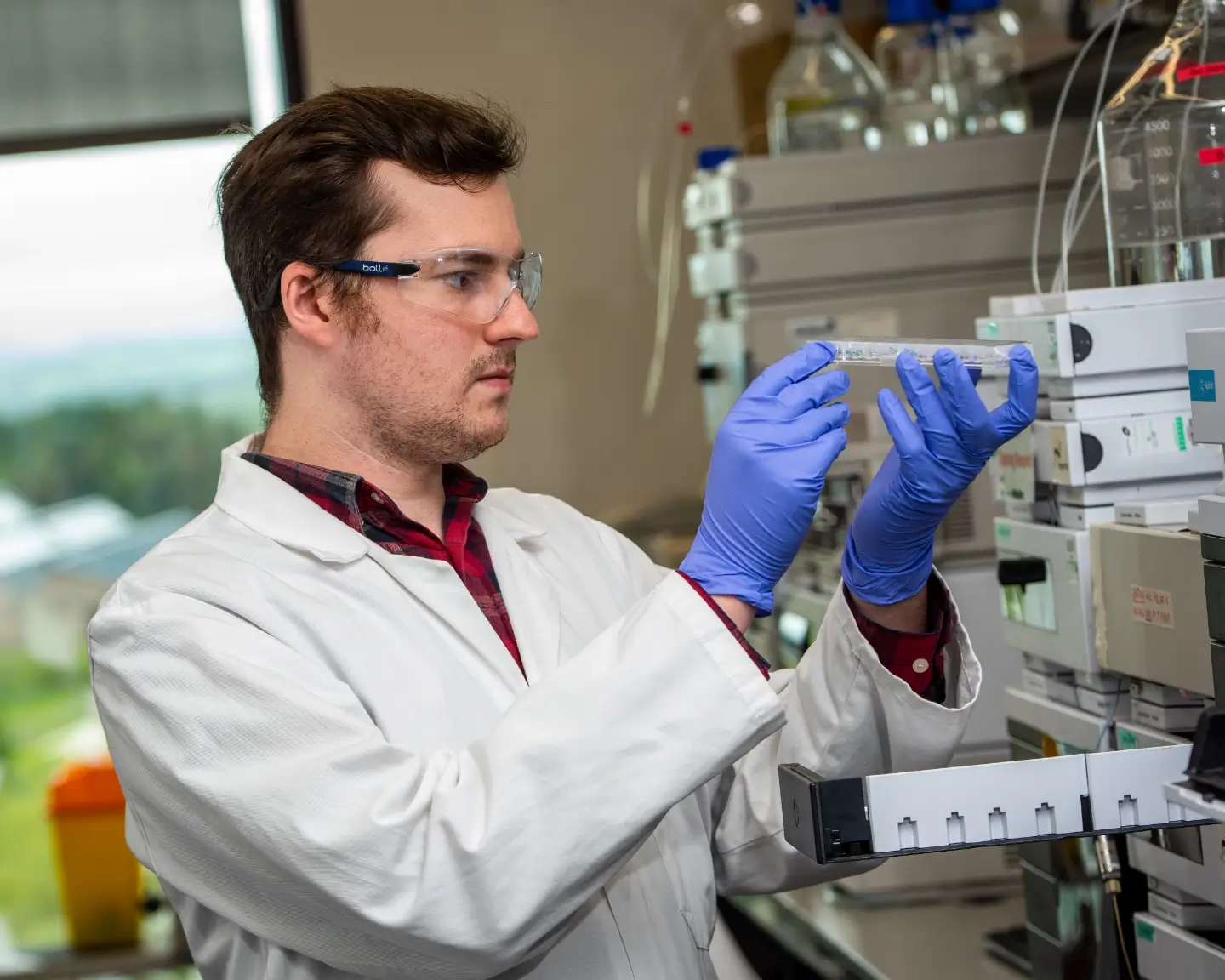

In-process Controls and Monitoring (IPC/IPM)

We develop IPC/IPM to monitor and ensure both process and product quality, achieving batch-to-batch reproducibility. Our comprehensive IPC/IPMs are designed to monitor critical process parameters (CPPs) essential for achieving the product's critical quality attributes (CQAs). This approach enables real-time adjustments to prevent costly batch failures and supports detailed documentation in line with regulatory standards and expectations.

Our IPC/IPMs can be developed to suit your process requirements, and include:

- Process monitoring: pH monitoring and control, dissolved oxygen (DO) levels, temperature control, agitation rate, nutrient feeding, foam control, and off-gas analysis.

- Metabolite monitoring: tracking of feedstocks and metabolites including by-products, such as organic acids, to measure inhibitory effects on cell growth/product quality and develop control strategies.

- Biomass monitoring: using optical density, dry cell weight, and wet cell weight measurements to assess cell growth.

- Product concentration and yield: analysis via SDS-PAGE, Western blot, and ELISA to confirm product presence and concentration.

- Contamination monitoring: routine checks to ensure microbial or cell line purity.

- Process residual clearance: Endotoxin, host cell protein (HCP), host cell DNA (HCDNA), Nuclease and Protease levels, Mycoplasma, antibiotics, and other process residuals. Our analytical capabilities allow for non-standard residuals to be monitored.